Safer Motoring for M Series Cars

- Webmaster

- Dec 3, 2020

- 4 min read

Thanks again to Bernd Bamberg

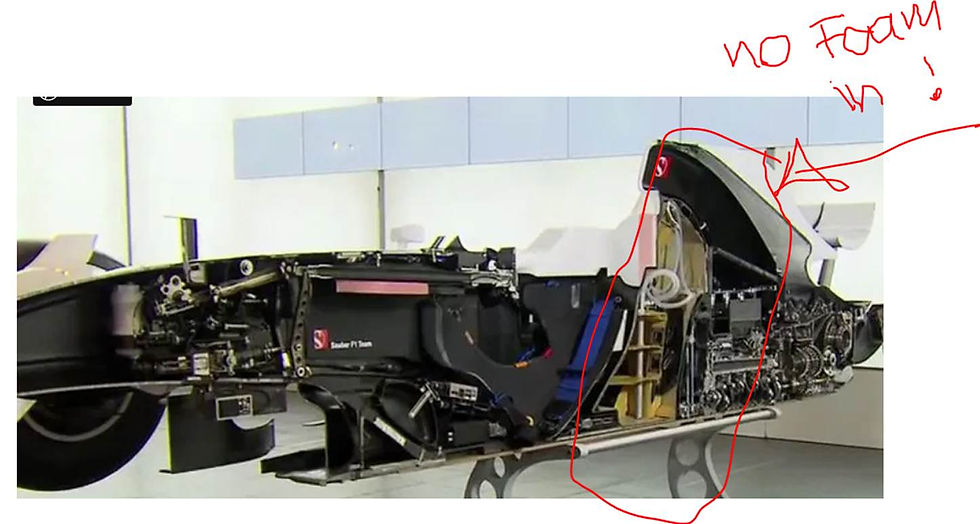

INFO : Modern F1 fuel tanks - No Explosion Suppressant Safety Foam (ESF) included

Quelle: Pool via REUTERS

The automobile authority FIA operates its own safety institute, the best accident researchers are involved there. The institution, which is very close to the heart of FIA President Jean Todt, is often financed by fines imposed on racing stables. An army of experts is constantly working on ever stricter regulations, because the vehicles are not only faster, but also technically demanding. Romain Grosjean's crash shows how safe Formula One has become - which doesn't mean that there are still some questions to be resolved: Why was the car able to shoot through the guardrails after the impact? Why were guardrails at the accident site, not other buffering barriers? How did the fire ignite so quickly and violently?

Quelle: AFP

In the first lap after the start, the medical car drove directly behind the peloton, so the professional rescuers could be on hand immediately in turn three. The medical car was chauffeured by South African Alan van der Merwe at the highest possible speed, with British Formula One racing doctor Ian Roberts on board. They received Grosjean after jumping over the guardrails, the track posts directly at the accident site sprayed the way for the accident victim fleeing the flames with fire extinguishers. Within 15 seconds, the first fire cannon had already been pointed at the burning wreck. Van der Merwe was happy and amazed afterwards "that Romain got out so quickly after such a crash." Roberts found the statement in a positive chain reaction: "Today, all the safety features we have introduced over the last 30 years have intertwined. If only one of them had not been, this accident could have been different."

No Foam protection was included

Qualified for all Military Uses

The U.S. Air Force, Navy, and Army (with the assistance of other agencies such as the Federal Aviation Administration) conducted extensive tests over many years - including exposure to HEI (High Explosive Incendiary) fire - to determine properties required in ESF to effectively protect aircraft and, at the same time, permit all fuel systems to function normally.

Applications

· Mitigates fuel spray in the event of rupture from compressive forces and minimizes explosions by the ignition of fuel vapors in the tank caused by electrical arcing, lightning strikes, or static discharge.

· Baffles fuel to control surging and eliminate sloshing, improves handling in high-performance vehicles and eliminates fuel ‘slapping’ noise in the tank.

· Cost-effective solution with the lowest initial cost of any explosion suppression system; can be easily installed and retrofitted into existing fuel tanks, very low weight penalty, and requires no maintenance.

Explosion Suppressant Safety Foam (ESF)

ESF reticulated polyurethane foams for explosion suppression and surge/noise mitigation are unique, environmentally-friendly materials designed for use in rigid and flexible (bladder type) fuel tanks in virtually any vehicle, vessel, or aircraft. It is suitable for any vehicle where the possibility of fuel tank explosion exists, or where surge/noise mitigation is required.

Conforming to Mil Spec MIL-B-83054, SAE-AIR-4170 or equivalent. This foam shall fill a minimum of 80 % of the volume of the fuel bladder. Where rapid refueling is expected, an anti-static foam conforming to Mil-Spec MIL-F-87260 (USAF) shall be employed.

ESF Type II Yellow compatibility Petrol

ESF Type III Blue Diesel / Methanol

Only displaces 3%

Contact Us

Large, odd-shaped and ungainly, and covered in ribs that hold together the up to 30 sections from which they are made, bag tanks are not things of beauty. Installed in the space at the tail end of the monocoque for reasons of safety, bag tanks are shaped to fill the contours behind the driver’s seat for the safest and most space efficient way of storing approximately around 30 gallons of fuel, keeping in mind that the maximum allowed fuel for an entire race is set to 110kg (thus 110 litres). Wide at the base, the tank extends up to the level of the driver’s neck, and protrudes forward not only to fit the cavity but to store the fuel low down in the car, which helps to keep the vehicle’s centre of gravity low. Studs fitted to the tank are inserted into the back of the driver’s seat and the sides of the tub to keep it from collapsing as it empties.

Keeping the fuel as low down as possible is aided by the fitting of two baffles. These rubber shelves prevent the fuel from sloshing around during cornering, which would impair the handling. Furthermore, keeping the fuel at the tank makes it easier to collect for delivery to the engine. There are two openings at the rear of the tank. The one at the bottom is for the mechanical pump, which picks up the fuel from the collector at the bottom of the tank and pressurizes it before it travels up the fuel lines to the engine. The second opening is at the top, and it’s through there that the fuel lines exit, with the opening being a self-sealing, frangible coupling to the fuel line. The tank is filled via an opening in either shoulder. Having an opening on each side was essential when refuelling was permitted, because not all pit garages are on the same side of the car. As with many F1 parts, the tank’s design is a compromise that enables it to fit into the smallest available space. Designers would prefer the tank to be tall and thin, to work in the most efficient way, but such a tank clearly wouldn’t fit into an F1 car.

Comments